Got questions? Send us an email:

info@hpbs.uz

Taisei Technology Center: A LEED Platinum Building of the Future and Circular Architecture in Action

The Taisei Technology Center is the research campus of Taisei Corporation located in Yokohama, Japan. At its core stands the ZEB Demonstration Building | Taisei’s Urban ZEB - an office building certified LEED-NC Platinum, rated CASBEE S, and awarded 5-Star BELS.

It operates as a living laboratory, where Taisei tests zero-energy technologies and circular resource strategies shaping the cities of the future.

Yokohama and Taisei’s Role in Climate Neutrality

The project is deeply embedded in the city’s long-term sustainability strategy:

- Yokohama Smart City Project - a flagship demonstration programme for next-generation energy systems and smart urban infrastructure.

- Yokohama Smart Business Association - since 2016, Taisei has been one of the key companies supporting the city’s transition toward a low-carbon and circular economy.

The ZEB building is an integral element of this ecosystem, demonstrating how net-zero energy performance, occupant comfort, and seismic resilience can be achieved simultaneously within a dense urban context.

Taisei Technology Center: A City of Laboratories

The Taisei campus itself functions as a miniature city, comprising:

- Laboratories dedicated to wind engineering, structures, acoustics, fire, lighting and thermal comfort, geotechnics and foundations, coastal and river processes, materials, and environmental studies.

- The Human Space Lab (ZEB) - a full-scale demonstration office environment.

Approximately 296 specialists work at the center, spanning departments of technology planning, innovation, intellectual property, urban and infrastructure engineering, production engineering, and advanced technologies.

Here, the ZEB building serves as a testbed, where solutions are validated before being deployed across real projects throughout Japan.

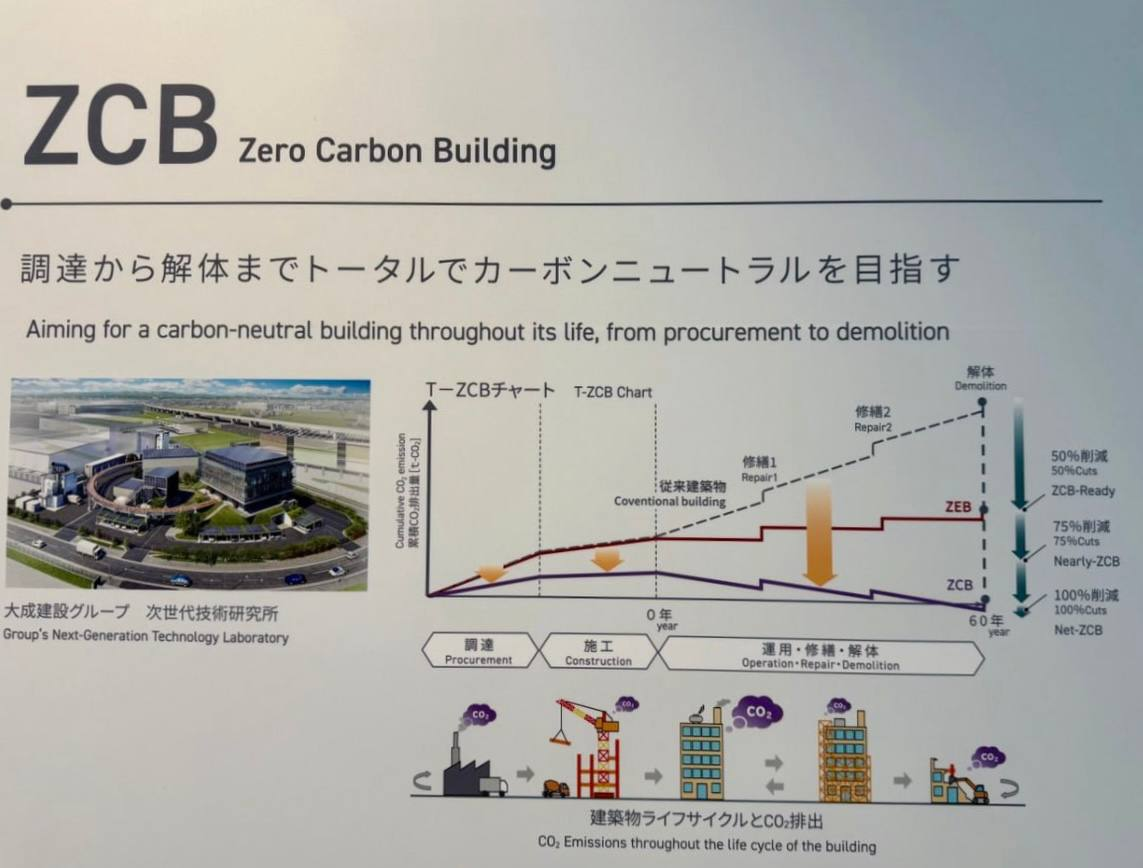

From Energy Efficiency to Zero Energy

Taisei’s guiding concept is straightforward yet ambitious:

«The building of the future harnesses natural energy, automatically optimises lighting and air-conditioning, reduces energy consumption to zero, and at the same time creates individually comfortable spaces - freeing people from energy-related stress.»

At a conceptual level, Urban ZEB is structured around three core principles:

- Vibrant Office - a lively, comfortable environment that supports focus and productivity.

- Zero Energy - maximum demand reduction combined with on-site generation to achieve a net-zero annual energy balance.

- Greater Reassurance - safety and business continuity preparedness, including seismic resilience and backup power systems.

The energy balance model illustrates this clearly:

- A conventional office building consumes 100% energy with no generation.

- The ZEB pilot achieves approximately 75% energy reduction through architectural and engineering measures, with the remaining 25% covered by on-site generation.

The result is a true annual balance of Production = Consumption = 0.

Architecture and Structure

- Location: Totsuka-ku, Yokohama, Kanagawa Prefecture

- Function: Office and laboratory facilities

- Configuration: Three above-ground floors plus a penthouse, above a seismic isolation pit

- Structure: Reinforced concrete with partially precast elements and a seismically isolated foundation

Both interior and facade finishes were selected with durability, energy efficiency, and material circularity as primary criteria.

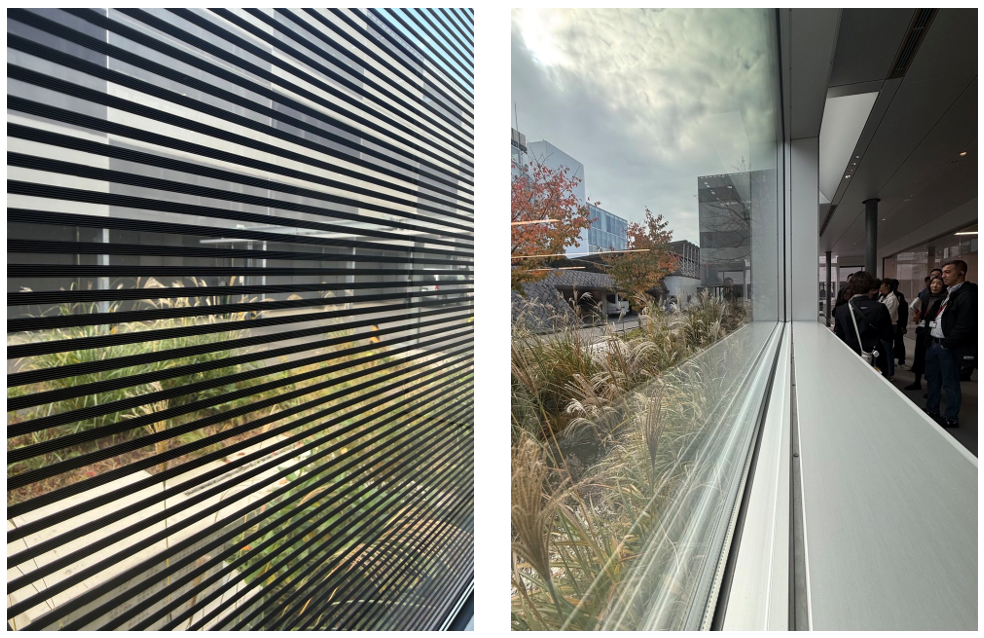

Facade as a Power Plant: Organic Thin-Film PV

A defining feature of Urban ZEB is its facade, incorporating organic thin-film photovoltaic modules integrated directly into the building envelope:

- Their lightweight and flexible form factor enables application on curtain walls and retrofit projects.

- The modules perform a dual function - acting as part of the thermal envelope while generating electricity.

- Colours and patterns can be customised to suit the architectural language of each building.

The roof is additionally equipped with conventional PV panels, completing a closed on-site generation loop.

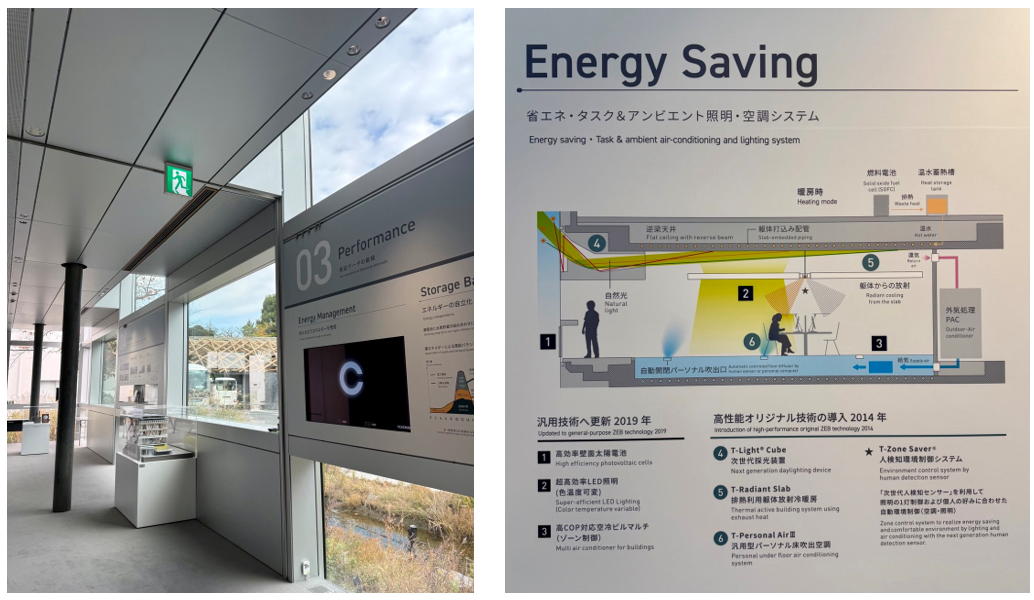

Intelligent Energy-Saving Systems

1. Lighting: From Daylight to Organic EL

The low-illumination task & ambient lighting system integrates:

- Maximum utilisation of daylight

- High-efficiency LED luminaires with tunable colour temperature

- Organic EL task lights at workstations

- Occupancy sensors that automatically eliminate unnecessary lighting

The lighting strategy follows a clear principle: a soft ambient background combined with targeted personal lighting exactly where it is needed.

2. T-Light Cube: Daylight Management

The T-Light® Cube system reflects incoming daylight from windows and redistributes it deeper into the interior through ceiling geometry. As a result:

- Workspaces receive soft, evenly diffused daylight

- Dependence on artificial lighting during daytime hours is significantly reduced

3. Climate Control: T-Radiant Slab and T-Personal Air II

The task & ambient air-conditioning system using exhaust heat consists of:

- T-Radiant Slab - a thermally active concrete slab with embedded piping, circulating water heated or cooled partly via exhaust-air heat recovery. The space is conditioned through radiant exchange, without draughts.

- T-Personal Air II - a personalised underfloor air-supply system that responds to occupant presence and individual preferences, rather than imposing a uniform setting across an entire floor.

4. T-Fresh Air: Smart Window and Ventilation Control

The T-Fresh Air system integrates:

- Data on wind conditions, outdoor and indoor temperature, and humidity

- Occupancy information

- Results from computational simulations

Based on this data, users receive recommendations on when to open or close windows, while ventilation and air-conditioning systems adjust automatically.

The building effectively educates occupants to live in an energy-efficient way without removing their sense of control.

Energy Management: T-Green BEMS and ZEB Navi

Energy performance is monitored and managed through T-Green BEMS, which:

- Displays real-time energy generation (PV, fuel cells) and consumption by end-use

- Visualises daily, monthly, and annual energy balances via ZEB Navi screens

- Provides engineers with optimisation data and occupants with intuitive feedback on behavioural impacts

Seismic Isolation and Business Continuity

Beneath the building, a short-stroke seismic isolation system is installed:

- Isolators are located within a dedicated pit below the structure

- The isolation stroke is optimised (approximately 30 cm), reducing spatial requirements

- During strong earthquakes, the building effectively “floats” on the isolators, while occupant comfort is maintained during minor and moderate events

This significantly increases the likelihood that the office will remain operational even after a major seismic event.

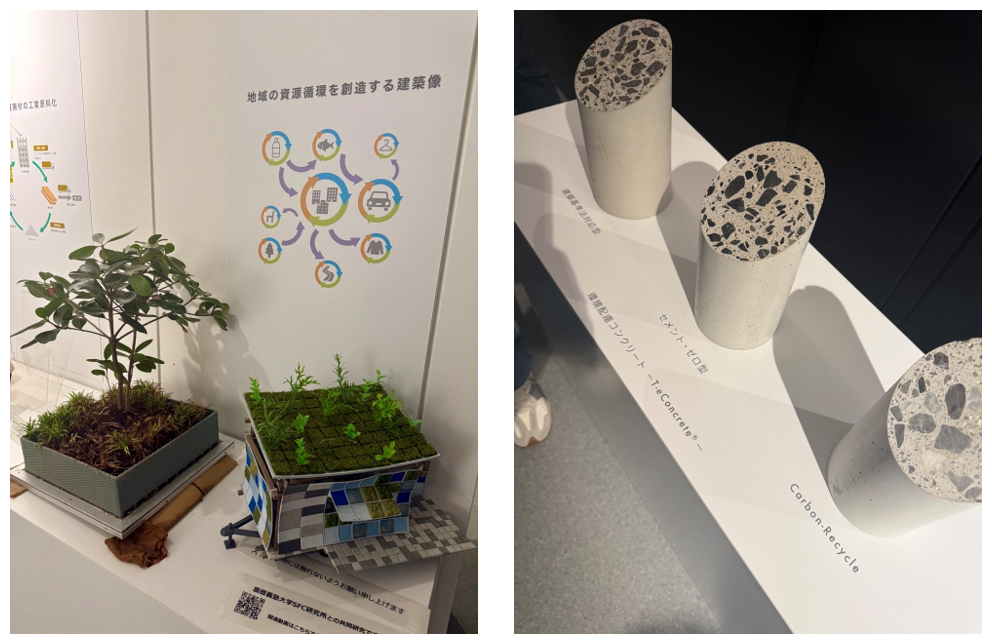

Circular Architecture: From In-Flow to Out-Flow

A key part of the visit focused on resource circulation, with Taisei viewing the building as part of an extended material lifecycle:

- In-flow - incoming streams such as marine plastics, packaging, textiles, timber, soil, and more. The goal is to match materials to their properties, prioritising lightweight, durable, and recyclable options.

- Stock - the building itself as a “material bank”, with detailed records of what is installed, how, and from what, enabling future disassembly and reuse.

- Out-flow - outgoing streams during renovation or demolition, designed to maximise reuse and recycling rather than disposal.

Upcycle Cabin: A Prototype of Circular Architecture

To make this philosophy tangible, Taisei developed the Upcycle Cabin (UC) - a small, mobile structure made entirely from secondary materials.

- A Story of a Resource-Circulating Society

Taisei presents a narrative of a future circular society:

- Community-based resource collection stations

- Local manufacturing using collected materials

- Digital systems managing resources at neighbourhood scale

- Partial return of materials to nature via biodegradable solutions

- Long-life architectural elements that remain for future use

- Continuous reintegration of materials into the economic cycle

The Upcycle Cabin acts as a node connecting people, waste, and architecture.

- Cabin Design Concept

Key principles include:

- Acceptance of resources even in small quantities to encourage community participation

- Replaceability without disrupting the overall system

- Full disassembly into individual material components

- Mobility - deployable wherever and whenever needed, mounted on a trailer

- Materials and Mock-Up

The prototype incorporates diverse secondary materials, including:

- Skylights made from refillable detergent packaging

- Artificial turf for roof greening

- Wall panels manufactured from recycled paper nappies

- Panels composed of PP bands and wood chips with moss

- Flooring from timber sourced through forest thinning

- Insulation panels made from recycled plastic

- Windows fabricated from Chemilisa acrylic

- A multifunctional 3D-printed window

Each component demonstrates how a specific waste stream can be transformed into a functional building element.

Quantifying Circularity: MCI and Detachability Index

Taisei evaluates performance using quantitative metrics:

- Material Circularity Indicator (MCI)

For materials such as reclaimed steel, chestnut beams, aluminium frames, timber elements, plastic seismic walls, and connectors, the resulting MCI reaches 97%, meaning nearly the entire structure consists of recycled or reusable materials.

- Detachability Index (DI)

DI measures how easily the structure can be dismantled into mono-materials:

● overall for the object - 70%;

● structure - 63%, envelope - 100%, space plan - 89%.

This is achieved through:

● standardised 400 × 400 mm panels made from a single material;

● fixings and joints designed for repeated removal and re-installation.

Madaster: Digital Material Passports

To manage circularity, Taisei uses Madaster (Netherlands) - a digital registry of materials and built assets.

The process involves:

- Uploading data from Excel, BIM/CIM models, and environmental material indicators

- Automated calculation and visualisation of circularity metrics

- Treating the building as a resource bank, with information on reuse potential, degradation, and future residual value

Architecture thus becomes not only a physical asset, but a financial and material resource.

Technical developments: demountable joints and timber reuse

Taisei presented two key development streams.

1. Joining methods with high detachability and reattachability

- demountable wall panels assembled from a single material;

- specialised timber joints that transfer structural loads without complex machining, while remaining easy to dismantle.

2. Attachment systems for timber reuse

- dry joint systems that allow historical timber from temples and shrines to be reused without compromising its cultural value;

- a design approach combining remountability and structural resilience.

Through these innovations, architecture becomes not only a technical solution, but also a means of carefully extending the life of cultural heritage within new construction projects.

Education and community engagement

The In-flow - Stock - Out-flow approach also shows that children themselves:

- collect and sort waste;

- place it into transparent sample panels;

- literally walk on a «floor of the future» assembled from those very modules.

As a result, the ZEB building and the Upcycle Cabin become not only engineering objects, but also platforms for educational programmes and for shaping a new culture of resource use.

What matters for our projects

For our projects in Uzbekistan and Central Asia, this experience serves as a strong practical benchmark for integrating green certification, ZEB | ZCB, circular economy principles, and education within a single, coherent space.

The visit to the Taisei Technology Center offered a highly concentrated set of practical insights:

- a building certified LEED Platinum, CASBEE S, and 5-Star BELS operates successfully in a real urban environment - not only on paper;

- zero energy performance is achieved not through a single «magic solution», but through a system of coordinated measures: a facade power plant, intelligent lighting control, thermally active slabs, personalised air supply, smart control systems, and energy storage;

- the project is embedded from the outset in city-level climate neutrality strategies and resource cycles - from material selection to reuse and end-of-life scenarios;

- the small Upcycle Cabin demonstrates how the same principles can be scaled down to the level of a neighbourhood, school, or local community.

For Uzbekistan and the cities of Central Asia, this experience offers several direct and practical lessons:

- The ZEB approach can and should be integrated with international standards such as LEED, BREEAM, and EDGE, alongside national rating systems.

- Demonstration projects embedded in research campuses can serve as laboratories for future cities.

- Without a circular material strategy, zero operational energy alone will not deliver true sustainability - a full life-cycle perspective is essential.

LEED Certification for your project

The HPBS team provides LEED certification services for projects of any scale — from individual buildings to large urban developments.

For inquiries, please contact: info@hpbs.uz